July 15, 2024

Over the past decade, the field of masonry has witnessed significant advancements in technology aimed at enhancing the efficiency, precision, and safety of bricklaying processes. From robotic bricklayers to automated masonry systems, these innovations are transforming traditional construction methods and revolutionizing the way masons and bricklayers work. Let's dive into some of the key technological developments that have emerged in the last 10 years and their impact on the masonry industry. What items are you currently using on the jobsite? Share your story. Email info@brickworkssupply.com

Robotic Bricklayers

Robotic bricklayers, also known as bricklaying robots or robotic arms, are automated machines designed to lay bricks with precision and speed. These robots are equipped with sophisticated sensors, cameras, and algorithms that enable them to analyze the construction site, identify the optimal brick placement, and execute laying patterns with remarkable accuracy. By automating the bricklaying process, robotic bricklayers can significantly increase productivity, reduce labor costs, and minimize errors associated with manual bricklaying. Companies like Fastbrick Robotics and Construction Robotics have developed robotic bricklaying systems such as the Hadrian X and SAM (Semi-Automated Mason), which are being deployed on construction sites around the world.

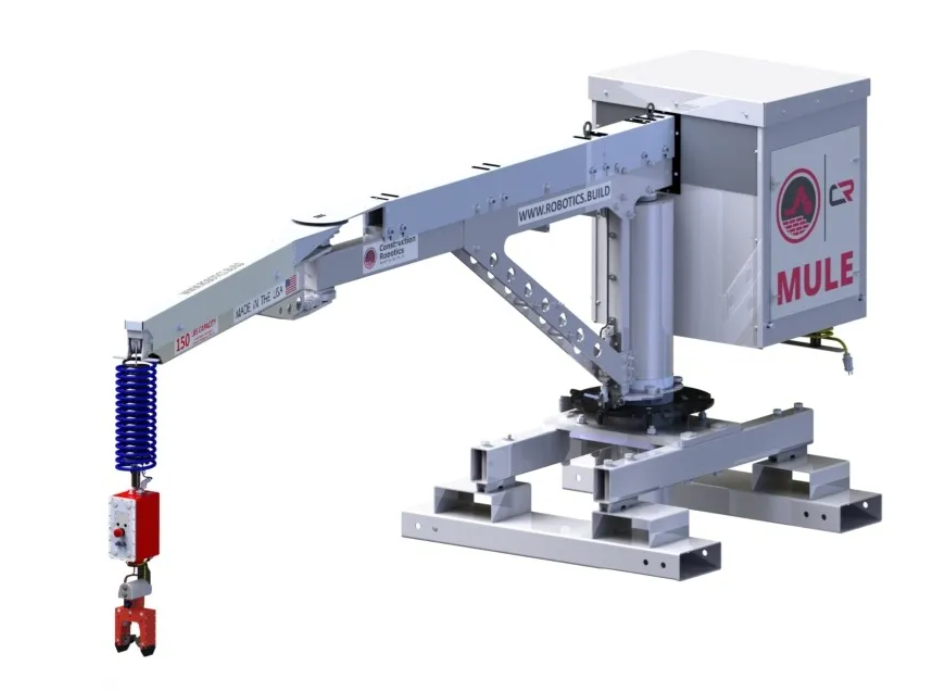

Autonomous Vehicles (Mules)

Autonomous vehicles, often referred to as mules, are robotic platforms designed to transport materials and equipment on construction sites. These vehicles are equipped with sensors, GPS navigation systems, and obstacle detection technology, allowing them to navigate complex terrain and transport heavy loads safely and efficiently. Mules can be used to transport bricks, mortar, tools, and other materials between storage areas and work zones, reducing the need for manual labor and streamlining logistics on construction sites. Companies like Construction Robotics and Hilti have developed autonomous vehicles such as the MULE (Material Unit Lift Enhancer) and the Jaibot, which are designed to assist masons and bricklayers by carrying materials and equipment to and from the job site.

3D Printing Technology

3D printing technology has made significant strides in recent years, offering new possibilities for creating complex architectural elements and structures using brick and other masonry materials. Using robotic arms or gantry systems, 3D printers can extrude layers of mortar or concrete in precise patterns to build walls, columns, and other masonry components layer by layer. 3D printing allows for greater design flexibility, enabling architects and designers to create intricate and customized masonry elements that would be difficult or impossible to achieve using traditional construction methods. Companies like COBOD and Apis Cor are leading the way in 3D printing construction technology, developing systems capable of printing entire buildings using brick and other masonry materials.

Augmented Reality (AR) and Virtual Reality (VR)

Augmented reality (AR) and virtual reality (VR) technologies are being used to enhance masonry training, design visualization, and project planning. AR applications allow masons and bricklayers to overlay digital information, such as building plans, measurements, and instructions, onto the real-world construction site, providing real-time guidance and assistance. VR simulations enable users to immerse themselves in virtual construction environments, allowing them to practice bricklaying techniques, explore design concepts, and visualize finished projects before construction begins. By integrating AR and VR into masonry workflows, companies can improve training outcomes, reduce errors, and enhance collaboration between architects, engineers, and construction teams.

Building Information Modeling (BIM)

Building Information Modeling (BIM) software has become increasingly prevalent in the construction industry, offering masons and bricklayers powerful tools for project planning, coordination, and documentation. BIM platforms allow users to create digital models of buildings and structures, incorporating detailed information about materials, dimensions, and construction sequences. Masons and bricklayers can use BIM software to visualize construction projects in 3D, identify potential conflicts or errors in advance, and optimize construction sequences to improve efficiency and minimize waste. By leveraging BIM technology, companies can streamline communication, improve project coordination, and enhance overall project outcomes.

The last decade has seen remarkable advancements in masonry technology, with innovations such as robotic bricklayers, autonomous vehicles, 3D printing, AR/VR, and BIM revolutionizing traditional bricklaying processes. These technologies hold the promise of increased productivity, improved safety, and enhanced project outcomes for masons, bricklayers, and construction companies alike. As these technologies continue to evolve and become more widespread, the future of masonry looks brighter than ever before. What have you used on your jobsites? Do you look forward to the way technology can assist in supporting the bricklaying industry now and into the future? We’d like to hear your story and possibly be shared in a future article. Email info@brickworkssupply.com

Find Your Store

IA | Des Moines

-

4601 NW Urbandale Drive, Suite 112

Urbandale, Iowa 50322

- Phone: 515-219-7842

- Hours: 07:30 am - 04:00 pm

IL | Bridgeview

-

7542 West 73rd Street

Bridgeview, Illinois 60455

- Phone: 708-607-9430

- Hours: 07:00 am - 03:00 pm

IL | Champaign

-

3200 W. Springfield

Champaign, Illinois 61822

- Phone: 217-439-4348

- Hours: 07:00 am - 03:30 pm

IL | Chicago

-

850 W. Pershing Road

Chicago, Illinois 60609

- Phone: 773-923-3771

- Hours: 07:00 am - 03:00 pm

IL | Des Plaines

-

821 Seegers Road

Des Plaines, Illinois 60016

- Phone: 847-860-6806

- Hours: 07:00 am - 03:00 pm

IL | Naperville

-

1760 North Aurora Road

Naperville, Illinois 60563

- Phone: 630-864-5711

- Hours: 07:00 am - 03:00 pm

IL | New Lenox

-

1300 West Maple Street

New Lenox, Illinois 60451

- Phone: 815-680-2971

- Hours: 07:00 am - 03:00 pm

IL | Schaumburg

-

409 West Wise Road

Schaumburg, Illinois 60193

- Phone: 847-860-6242

- Hours: 07:00 am - 03:00 pm

IL | Springfield

-

800 South 9th Street

Springfield, Illinois 62703

- Phone: 217-492-8544

- Hours: 07:30 am - 03:00 pm

IN | Carmel

-

430 West Carmel Drive

Carmel, Indiana 46032

- Phone: 317-597-8767

- Hours: 07:30 am - 04:00 pm

IN | Chesterton

-

1631 Pioneer Trail

Chesterton, Indiana 46304

- Phone: 219-250-9859

- Hours: 07:30 am - 04:00 pm

IN | Evansville

-

3401 Mt Vernon Ave

Evansville, Indiana 47712

- Phone: 812-993-4472

- Hours: 08:00 am - 04:00 pm

IN | Fort Wayne

-

3000 N Wells St

Fort Wayne, Indiana 46808

- Phone: 260-264-7468

- Hours: 07:30 am - 04:00 pm

IN | Indianapolis Edgewood North

-

5007 W 96th St

Indianapolis, Indiana 46268

- Phone: 317-751-2334

- Hours: 08:00 am - 04:30 pm

IN | Indianapolis Epler Ave

-

1580 E Epler Ave

Indianapolis, Indiana 46227

- Phone: 317-779-1670

- Hours: 07:30 am - 04:00 pm

IN | Indianapolis Shelby St

-

5518 Shelby Street

Indianapolis, Indiana 46227

- Phone: 317-779-3090

- Hours: 08:00 am - 04:30 pm

IN | Lafayette

-

1799 North 9th Street

Lafayette, Indiana 47904

- Phone: 765-476-0452

- Hours: 07:30 am - 04:00 pm

IN | South Bend

-

918 Oliver Plow Ct

South Bend, Indiana 46601

- Phone: 574-777-0167

- Hours: 07:30 am - 04:00 pm

MD | Baltimore

-

4150 Hayward Avenue

Baltimore, Maryland 21215

- Phone: (410) 220-2363

- Hours: 07:00 am - 04:00 pm

MD | Upper Marlboro (DC)

-

8315 Old Marlboro Pike

Upper Marlboro, Maryland 20772

- Phone: (301) 701-5160

- Hours: 07:30 am - 04:00 pm

MI | Waterford

-

6315 Highland Road

Waterford, Michigan 48327

- Phone: 248-392-3980

- Hours: 07:00 am - 03:00 pm

MI | Whitmore Lake

-

6556 Whitmore Lake Rd

Whitmore Lake, Michigan 48189

- Phone: 734-212-8454

- Hours: 08:00 am - 04:00 pm

MN | Bloomington

-

520 West 86th Street

Bloomington, Minnesota 55420

- Phone: 952-206-5490

- Hours: 07:30 am - 04:00 pm

NE | Omaha

-

13801 Industrial Road

Omaha, Nebraska 68137

- Phone: 402-235-5567

- Hours: 07:30 am - 04:00 pm

PA | Reading

-

200 Hartman Road

Muhlenberg, Pennsylvania 19605

- Phone: 610-686-7711

- Hours: 07:00 am - 03:30 pm

VA | Manassas

-

7413 Cushing Road, Suite 100

Manassas, Virginia 20109

- Phone: 703-263-8057

- Hours: 07:00 am - 03:30 pm